Thermoplastic elastomers (TPEs) are a class of copolymers (typically a mixture of rubber and plastic) that contain materials with both elastomeric and thermoplastic properties.

Thermoplastic elastomers (TPEs) are a class of copolymers (typically a mixture of rubber and plastic) that contain materials with both elastomeric and thermoplastic properties.

Automotive Thermoplastic Elastomers (TPE) Market size may have positive outlook in manufacturing bumper, internal lining, foot mats and external styling car body.

SBS modified bitumen roofs or styrene butadiene styrene roofs are made by modifying the asphalt in a modified bitumen roof. This forms a polymer mesh inside the bitumen giving it rubber-like consistency.

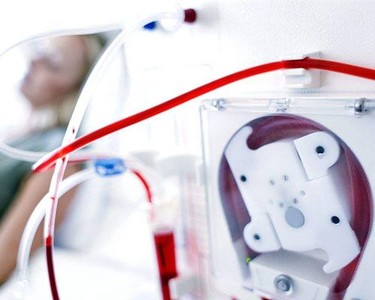

The global medical elastomers market is mainly driven by factors such as advancements in the thermoplastic elastomer (TPE) processing technology, growing demand for medical products incorporating elastomers, increasing government support, and rising awareness among people on improved healthcare facilities.

The global SEBS market is expected to grow at an exponential CAGR in the years to come. A thermoplastic elastomer that comprises styrene in it is known as SEBS. SEBS is also popularly known in its expanded form that is Styrene Ethylene Butylene Styrene.

Hot melt adhesives, also known as hot glue, and are in the form of thermoplastic adhesive which is applied using a hot glue gun. The variety of polymers in this class is wide and includes both natural and synthetic ones. It is commonly sold as solid cylindrical sticks of various diameters and can also be applied by spraying or dipping.

Thermoplastic elastomer compounds have a soft touch that is appealing and beneficial for consumer goods. TPEs are also useful in seals or in bottle-cap liners.

Road signs and road marking with paint, commonly known as road marking paint, there are room temperature type, heating type and melting type.

The Middle East & Africa contact adhesives market is expected to witness a CAGR of approximately 4.40% during the forecast period, 2018 - 2023.

Hydrocarbon resins are amorphous thermoplastic polymers produced by polymerization of unsaturated hydrocarbons. The feedstock are various by-products of naphtha crackers.1 These resins have typically a low molecular weight ranging from about 400 to 5000 g/mol. The three main types are C5 aliphatic, C9 aromatic, and DCPD cycloaliphatic resins.