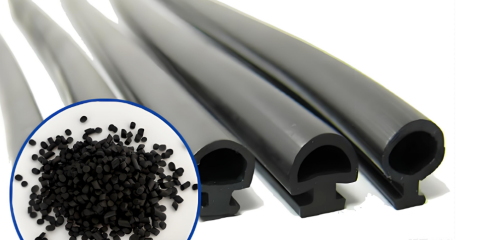

How to select TPE sealing strips, sealing rings, and SEBS substrate for different application scenarios? I. Application Positioning of SEBS-based TPE Seals As the core substrate of TPE, SEBS is widely used in sealing applications due to its excellent flexibility, weather resistance, processability, and halogen-free eco-friendly properties. Compared with TPU and TPV, its performance differences and applicable scenarios are clearly defined: 1. SEBS-based TPE Core advantages: outstanding flexibility, high processing efficiency (compatible with injection molding and extrusion processes), moderate weather resistance, eco-friendly and non-toxic properties, and low cost control difficulty. Drawbacks: Its wear resistance is inferior to TPU, its high-temperature performance is weaker than TPV (with a maximum long-term usage temperature of 80°C), and its oil resistance is mediocre. Ideal for sealing applications: Suitable for scenarios requiring moderate to low wear resistance, heat resistance, and oil resistance, particularly for sealing products with specific demands for environmental compliance, tactile performance, and manufacturing efficiency. 2. TPU Core advantages: high wear resistance, excellent elasticity, outstanding oil resistance, and high mechanical strength; Shortcomings: The weather resistance is average, yellowing is likely to occur with prolonged use, low-temperature toughness is poor, and the processing process is highly temperature-sensitive. Suitable for sealing applications: Primarily designed for high-wear dynamic sealing scenarios (e.g., hydraulic system seals) and oil-based environments. 3. TPV Core advantages: Exceptional high-temperature resistance (operating at up to 120°C for extended periods), outstanding weather resistance, remarkable anti-aging capability, and excellent compression permanent deformation performance. The disadvantages are: poor processing fluidity, relatively high material cost, narrow range of flexibility adjustment; Suitable for sealing applications: Engine sealing gaskets in high-temperature environments, and exterior building and automotive sealing components for outdoor use. Conclusion: SEBS-based TPE seals are better suited for applications requiring moderate to low wear resistance, weather resistance, and high-temperature performance, while emphasizing environmental friendliness, tactile comfort, processing efficiency, and cost control. Beyond these parameters, TPU or TPV should be prioritized. 2. SEBS Precision Selection Solutions for Various Scenarios SEBS selection is based on five key criteria: molecular structure (linear or star-shaped), styrene content, molecular weight, functional modification, and formulation compatibility, all tailored to specific application scenarios. 1. Car interior sealing strip Application location: Door and dashboard gap seal, seat slide rail seal Core requirements: Excellent softness and rebound, minimal permanent compression deformation, moderate weather resistance (UV and aging resistance), odor-free (compliant with automotive VOC standards), and stable processing performance (no shrinkage marks during extrusion or injection molding). SEBS selection parameters: Structure: Star-shaped SEBS (branching structure provides superior elasticity and resilience, with permanent compression deformation ≤30%) Styrene content: Medium styrene content balances flexibility and mechanical strength, Shore hardness A 30-50 Molecular weight: High molecular weight enhances the tensile strength and tear resistance of the material, preventing deformation during long-term use. Grade requirement: Automotive-grade (meets VOC/odor standards, such as ISO 14001 environmental certification) Key formulation modifications: Composite paraffin-based white oil (30%-50% additive) enhances softness; addition of antioxidants, UV stabilizers, and carbon black fillers improves weather resistance; PP (5%-10%) is incorporated to optimize processing and molding properties. 2. Medical Device Sealing Ring/Sealing Gasket Application location: syringe seal, catheter connector seal, medical device waterproof gasket Core requirements: Biocompatibility (compliant with ISO 10993 and USP Class VI standards), odorless and non-toxic, low leaching, soft and conforming (non-invasive to human tissues), resistant to disinfection environments (e.g., alcohol and hydrogen peroxide wipes) SEBS selection parameters: Structure: Prioritize linear SEBS Styrene content: Low styrene content ensures high flexibility and low-temperature toughness, with Shore hardness A 20-40 Molecular weight: medium molecular weight, balancing processability and sealing reliability to avoid small molecule precipitation Grade requirement: Medical grade (free from heavy metals and phthalates, with approved biocompatibility test results) Key points for formula modification: Use medical-grade white oil with an addition rate of 25%-40%; avoid stabilizers containing heavy metals and prioritize hindered phenolic antioxidants; a small amount of POE (polyolefin elastomer) can be added to enhance low-temperature toughness, making it suitable for refrigerated environments. 3. Sealing for doors/windows and small appliances in mid-to-low-end buildings Application: Sealing gaps in sliding doors/windows, sealing rings for small appliances (e.g., rice cooker/sealer, humidifier waterproof ring) Core requirements: balanced mechanical properties (tensile strength ≥3 MPa, elongation at break ≥300%), high processing efficiency (fast extrusion speed, burr-free injection molding), wide temperature range (-20°C to 70°C), and controllable cost SEBS selection parameters: Structure: Linear + Star-shaped SEBS blend (linear SEBS enhances tensile performance, star-shaped SEBS improves elasticity and compressive deformation resistance, blending ratio 7:3 or 6:4) Styrene content: 25%-30% (moderate styrene content ensures both softness and stiffness, Shore hardness A 40-60) Molecular weight: medium to high molecular weight (Mn=90,000-130,000), avoiding insufficient strength caused by low molecular weight or processing difficulties induced by high molecular weight. Grade: Industrial-grade (RoHS compliant) Key formulation modifications: Incorporate paraffin-based white oil (cost-effective, 35%-55% content); add talc (5%-10%) to enhance dimensional stability; and blend with a small amount of EVA (ethylene-vinyl acetate copolymer) to improve interfacial adhesion, meeting the bonding requirements for doors, windows, and profiles. 4. Consumer Electronics Sealing Strip Location: Earphone waterproof ring, phone stand seal Core requirements: Ultra-soft (邵氏硬度 A 15-30), weather resistance (anti-yellowing), resistance to minor friction, and high processing accuracy (flawless thin-walled molding without flash) SEBS formulation parameters: Linear SEBS (low styrene content, medium molecular weight) combined with medical-grade white oil and anti-yellowing agents, ensuring long-term odor-free and yellowing-free performance. III. Key Considerations for SEBS Selection Processing techniques for molecular weight matching: High-molecular-weight SEBS is ideal for extrusion molding (e.g., long strip seals), while medium and low-molecular-weight variants are better suited for injection molding (e.g., small gaskets or complex sealing gaskets). Styrene content positively correlates with hardness: higher styrene content results in greater material hardness and rigidity, while reducing flexibility. The邵氏硬度 must be precisely matched according to the specific application requirements. Enhanced environmental resistance: For applications involving minor oil contamination (e.g., kitchen appliances), select SEBS with ≥98% hydrogenation or incorporate a small amount of oil-resistant resin (e.g., EPDM powder). Cost optimization: For mid-to-low-end applications, 10%-20% PP or PE can be blended to reduce SEBS usage; high-end applications (e.g., automotive, medical) require high-purity SEBS to avoid performance degradation from impurities.