I. Types and Characteristics of Pressure-Sensitive Adhesives 1.Natural Rubber-Based Pressure-Sensitive Adhesives II. Common Additives and Their Functions in Pressure-Sensitive Adhesives III. Innovative Pressure-Sensitive Adhesives (PSAs) and Their Application Areas

Pressure-sensitive adhesives are generally classified based on their base polymers. The main types and their characteristics are as follows:

Characteristics: Strong initial tack, good flexibility, low raw material cost; however, the molecular chains contain unsaturated bonds, making them prone to oxidation and aging. They require antioxidants and have relatively poor temperature and weather resistance.

2. Synthetic Rubber-Based Pressure-Sensitive Adhesives (SBR, SIS, SBS, etc.)

SBR (Styrene-Butadiene Rubber): Wide adhesion range, moderate cost, better aging resistance than natural rubber;

SIS/SBS: SIS has extremely high initial tack and good low-temperature flexibility, while SBS has higher cohesion. Both are suitable for hot-melt pressure-sensitive adhesives, although SIS has weaker weather resistance compared to SBS.

3. Acrylic Pressure-Sensitive Adhesives

Characteristics: Excellent weather resistance, water resistance, and temperature resistance; environmentally friendly with low VOC content; wide adhesion range (adhesive to both polar and non-polar substrates). They can be solvent-based, emulsion-based, or hot-melt, with emulsion-based being more environmentally friendly.

4. Silicone-Based Pressure-Sensitive Adhesives

Characteristics: High-temperature resistance (long-term above 200°C), low-temperature resistance, chemical corrosion resistance; suitable for special extreme environments. However, they are costly and have relatively weak initial tack.

1. Tackifiers

Main Types: Rosin resins, terpene resins, petroleum distillate (C4/C5/C6) polymer resins

Function: Increase system Tg, enhance polymer modulus, improve shear strength, elongation, and adhesion; small amounts of stearic acid, wool wax, paraffin, and other additives can significantly reduce adhesion (without affecting rheological properties).

2. Plasticizers

Main Types: Mineral oils, etc.

Function: Reduce tape peel force and cohesive strength (can be used to lower the unwind force of single-sided tapes), improve process operability (lowering melting temperature and solution viscosity), and simultaneously reduce costs.

3. Antioxidants

Applicable Scenarios: Pressure-sensitive adhesives based on polymers containing unsaturated bonds, such as natural rubber

Function: Protect against oxidation, aging caused by high temperature and UV light, and stabilize adhesive layer performance. Mixed antioxidants can optimize protective effects.

4. Colorants / Fillers

Main Types: Titanium dioxide, zinc oxide, silica, calcium carbonate, carbon black, etc.

Function: Provide color to the adhesive layer, enhance cohesive strength and adhesion; non-modified fillers like calcium carbonate can reduce costs; carbon black also provides UV stability. Excessive addition may cause the adhesive layer to become hard and brittle, losing adhesion.

5. Modified Fillers / Crosslinking Agents

Main Types: Isocyanates, titanates, diamines / polyamines, hydrazine additives, oil-soluble phenolic resins, basic fillers / zinc resin acid fillers

Function: Improve creep resistance (such as in high-strength strapping tapes), increase cohesive strength; oil-soluble phenolic resins can be used for high-temperature applications (such as electronic masking tapes), and basic fillers can catalyze the reaction of phenolic resins with rubber.

1. Delayed-Curing Pressure-Sensitive Adhesive

Characteristics: Non-PSA state when shipped; converts to PSA upon heating before application

Application Areas: Label bonding (scenarios requiring precise control over the curing time).

2. Functional Permeable / Non-Permeable Pressure-Sensitive Adhesive

Characteristics: Controllable water vapor permeability

Application Areas: Medical industry (permeable tapes for pregnancy/diabetes testing), drug delivery (transdermal tapes containing active ingredients such as nicotine and vitamins).

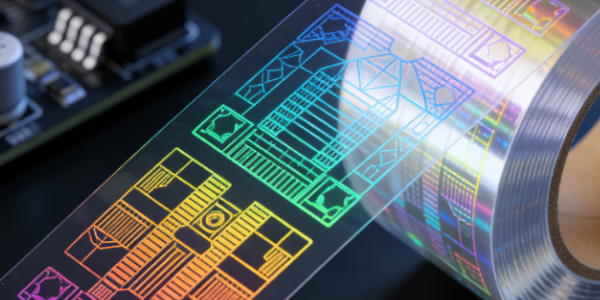

3. Double-Sided Coated Foam Pressure-Sensitive Adhesive

Characteristics: Strong and reliable, lightweight, die-cuttable; combines adhesion, sealing, and vibration absorption functions

Application Areas: Electronics industry (replacing traditional chemically activated glues for bonding flexible circuits, electromagnetic compatibility shielding, protective masking, and reliable bonding of microelectronic components).

4. UV-Curable Pressure-Sensitive Adhesive

Characteristics: Addresses the insufficient temperature resistance of traditional thermoplastic tapes

Application Areas: High-temperature environments (e.g., shielding tapes in the electronics industry).

5. Smart / Multifunctional Pressure-Sensitive Adhesive Tapes

Types: Transparent invisible label tapes, low-temperature frozen food packaging label tapes, removable label tapes, scratch-resistant / scented label tapes, tamper-evident tapes (integrating ink, substrates, holographic technology), RFID-integrated tapes

Application Areas: Logistics traceability, food packaging, anti-counterfeiting labels, consumer electronics labeling, etc.