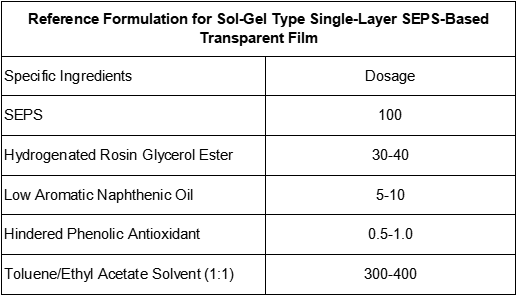

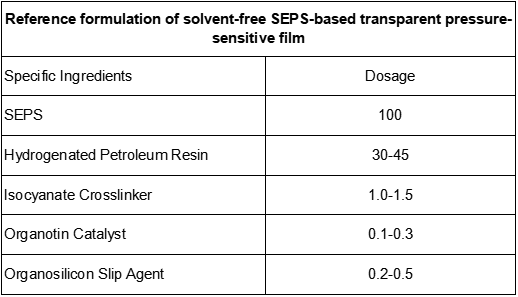

I.Solvent-Based Transparent Pressure-Sensitive Adhesive Film Formulation (Suitable for Precision Industrial Applications) This formulation is suitable for coating PET/PE substrates, with the core advantages being a mature coating process, initial adhesive strength of 18N/25mm, and holding adhesion of over 28 hours. It also offers a light transmittance of ≥91% and haze ≤4.2%, making it fully compatible with precision device laser-cut protective films (such as 304 stainless steel precision castings and optical glass blanks). The high transparency ensures accurate laser positioning, while the no-residue feature prevents scratches on the substrate surface, and its aging resistance suits a processing turnover cycle of 1 to 3 months. II.Solvent-free Transparent Pressure-Sensitive Adhesive Film Formulation (Suitable for High-End Eco-Friendly Applications) Its environmental performance meets FDA and EC 1935/2004 standards, making it suitable for high-end food packaging (such as chocolate and baked goods), medical protection (infusion set interface protective films), and high-end labels (automotive component identification): in food applications, it is odorless and free of migration risks; in medical applications, it meets biocompatibility requirements; in labeling applications, its low yellowing characteristics ensure clear appearance for 1–2 years. III. Selection Logic for the Two Types of Formulations

Priority is given to solvent-based formulations for precision industrial applications (where environmental restrictions are lenient and high adhesion and processing efficiency are required);

Priority is given to solvent-free formulations for food, medical, or high-end export applications (where strict environmental and compliance requirements apply).

Both types rely on SEPS's high hydrogenation level (98%) and low yellow index (≤5) to meet the combined high-end requirements for 'transparency + protection + compliance.