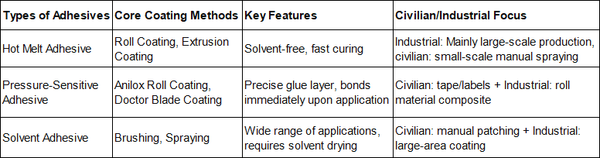

1. Hot melt adhesive coating method Anilox roller coating method 3. Solvent Adhesive Coating Methods

Hot melt adhesive needs to be heated and melted before coating, solvent-free, fast curing, suitable for high-speed production lines, the mainstream methods are as follows:

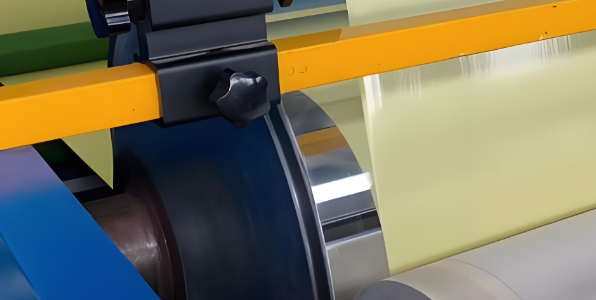

Roller coating method

Principle: The molten adhesive is transferred to the surface of the substrate through the rotation of the anilox roller and the coating roller, and the thickness of the adhesive layer is controlled by the accuracy of the roller texture

Applicable scenarios: large-scale continuous production of non-woven fabric composites (such as sanitary napkins and diapers), label primers, furniture edge banding, carpet adhesive backing, etc.

Extrusion coating method

Principle: After the hot melt adhesive is melted and pressurized by the screw extruder, it is directly coated on the surface of the substrate through the slit die, which can realize the coating of a thick adhesive layer.

Applicable scenarios: Automotive interior parts bonding, waterproof membrane composite, insulation material bonding, and other scenarios with high requirements for adhesive layer thickness.

Spraying method

Principle: After high-pressure atomization, the molten adhesive is sprayed onto the surface of the substrate in the form of a mist, and the adhesive layer is uniform and has good permeability.

Applicable scenarios: textile shaping, sofa sponge and fabric bonding, electronic product shell sealing and other irregular or porous substrates.

Scraping method

Principle: Use the gap between the scraper and the substrate to scrape the molten adhesive into a uniform thin layer, which is suitable for low-speed and high-precision coating.

Applicable scenarios: laboratory sample preparation, small batch special material coating.

2. Pressure sensitive adhesive coating method

Pressure-sensitive adhesives are divided into three categories: solvent-based, water-based, and hot-melt, and the coating method needs to be adapted to the gel type, and the mainstream methods are as follows:

Principle: Through the glue storage tank and texture of the anilox roller, the glue liquid is quantitatively transferred to the surface of the substrate, and the thickness of the glue layer is accurately controllable (micron level).

Applicable scenarios: The production of various tapes (stationery tapes, warning tapes), self-adhesive labels, and medical breathable tapes is the most commonly used coating method for pressure-sensitive adhesives.

Scraper coating method

Classification: It is divided into comma scrapers, scraper reversal coating, etc., and the thickness of the adhesive layer is controlled by adjusting the angle and pressure of the scraper.

Applicable scenarios: thick adhesive laminated pressure-sensitive adhesive products (such as foam tape, double-sided tape), large-area coil coating (such as protective film).

Spraying method

Principle: Spray the pressure-sensitive adhesive (solvent-based/water-based) and spray it, suitable for complex shape substrates.

Applicable scenarios: automotive interior parts adhesive, rubber and plastic products surface gluing, manual DIY glue spraying products.

Immersion method

Principle: The substrate is completely immersed in the pressure-sensitive glue, and after taking it out, it is dried and cured to form a uniform adhesive layer.

Applicable scenarios: gluing of small parts (such as label cores, sealing strips), and comprehensive gluing of non-woven fabrics and fabric substrates.

Solvent adhesives contain volatile organic solvents and need to be dried and cured. When applying, solvent recovery or exhaust equipment is required. The main methods are as follows:

Brush Coating

Principle: Manually applying the adhesive to the substrate surface using a brush or roller. The operation is simple and the cost is low.

Applicable Scenarios: Small-area manual bonding (such as woodworking repair, leather bonding, and home DIY).

Spray Coating

Principle: Atomizing the solvent adhesive through a spray gun for application. The adhesive layer is uniform and efficient, but solvent evaporation needs to be controlled.

Applicable Scenarios: Large-area substrate coating (such as leather processing, advertising canvas bonding, and automotive sheet metal bonding).

Roller Coating

Principle: Similar to hot-melt adhesive roller coating, the adhesive is transferred through rollers, suitable for continuous production.

Applicable Scenarios: Industrial production lines such as artificial leather, film lamination, and paper coating.

Squeegee Coating

Principle: Using a squeegee to control the thickness of the adhesive layer, suitable for high-viscosity solvent adhesives.

Applicable Scenarios: Thick adhesive layer bonding (such as stone joining, panel lamination) and precise application of specialty adhesives.

Comparison of the Core Differences Among the Three Adhesive Coating Methods