Low oil content, high resilience, transparent TPE, used in scenarios requiring high transparency, elasticity, low migration, and weather resistance, especially suitable for thermoplastic processing and secondary overmolding. II. Material Selection and Process Key Points

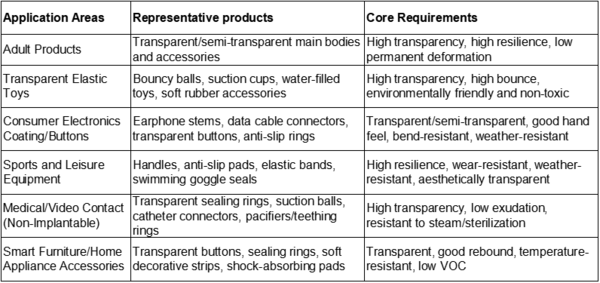

I. Typical application areas

Grade Selection: Prioritize high molecular weight SEPS, and blend with medium molecular weight SEPS to balance processability.

Oil Filling Control: Low oil fill (20–50 parts of hydrogenated white oil), to avoid increased haze and oil exudation.

Processing Technique: Use high-shear, deep-groove screws with a gradient heating strategy.

Compliance Requirements: Toys / Food / Medical applications require migration, heavy metal, and VOC testing, and use compliant additives and white oils.

III. Differences from Other Materials

Compared to TPU: SEPS-based TPE is softer and has rebound closer to rubber, better low-temperature toughness, but slightly inferior oil and abrasion resistance; suitable for transparent, high-rebound, low-permanent-deformation applications.

Compared to SEBS-based TPE: SEPS offers slightly better rebound and heat resistance, more suitable for high-rebound, low-oil-fill, weather-resistant transparent products.

Compared to PVC: Environmentally friendly, halogen-free, no plasticizer migration, better weather and aging resistance; suitable for high-end transparent and food/medical applications.