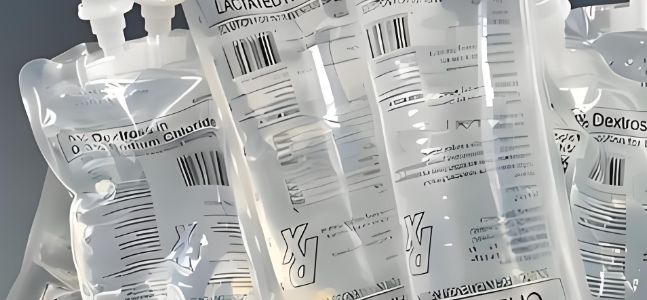

In the production of medical infusion bags, the choice of base material and its performance modification are directly related to drug safety and reliability of use. Medical random copolymer PP has become the mainstream base material due to its excellent chemical inertness, heat resistance, and processing adaptability. However, pure PP has drawbacks such as insufficient toughness and brittleness at low temperatures. Using medical-grade SEBS for toughening modification can precisely enhance the bag's bending resistance and low-temperature performance. By strictly controlling the amount of additives, migration risks can be completely avoided, making it suitable for infusion bags in different scenarios. Below are the targeted toughening solutions and key technical points for four types of medical infusion bags: I. Core Modification Logic Using medical-grade SEBS as the core modifier, combined with a medical-grade random copolymer PP substrate, the core advantage lies in the excellent compatibility between SEBS and PP, allowing for performance improvement without the need for large amounts of additives. The key control requirements are as follows: medical-grade white oil is used as a plasticizing aid, and its usage must be strictly limited to within 2% to avoid additive migration and contamination of the medicinal solution; SEBS should be selected in grades that meet medical biocompatibility standards, ensuring no interaction with various medicinal solutions and guaranteeing drug safety from the source. Through this modification scheme, the impact strength of the PP substrate can be increased by 3–5 times, and it can bend at low temperatures (-20℃) without cracking, fully meeting the stringent requirements of medical infusion bags. II. Targeted Toughening Solutions for Four Types of Medical Infusion Bags 2. Single-layer High-Toughness Infusion Bag for Cold Chain Transportation 3. Three-Layer Co-Extruded Infusion Bag III. Core Advantages of the Plan and Supply Assurance

1. General Single-Layer Transparent Infusion Bag

Applicable Scenarios: Directly contacts low-risk solutions such as glucose injections, saline, and common antibiotics. Suitable for storage and transportation at room temperature, it is the most widely used basic infusion bag in clinical practice.

Key Points of Toughening Formulation: Control the SEBS content within 10%. This proportion can significantly improve the toughness of the base material while ensuring the transparency of the infusion bag, preventing accidental damage during transport and use. The base material is high-transparency medical random copolymer PP, combined with less than 2% medical-grade white oil, ensuring the finished bag has high transparency, no haziness, and allows medical staff to easily observe the solution.

Core Advantages: The formulation is simple, highly process-stable, cost-controllable, and fully meets the biocompatibility and chemical inertness requirements of medical packaging materials.

Suitable Scenarios: Used for pharmaceutical liquids that require refrigerated transportation at low temperatures, such as biological products and certain antibiotics, and must maintain good toughness at -10°C to -20°C in a cold chain environment without risk of cracking. Key Points of Toughening Formulation: The amount of SEBS is increased to up to 13%. By dispersing a higher proportion of SEBS molecular chains, the low-temperature impact resistance of the PP substrate is enhanced; the substrate is made of low-temperature resistant medical-grade random copolymer PP, which works synergistically with SEBS to ensure that the infusion bag remains undamaged after repeated bending during cold chain storage, transportation, and use, thus maintaining the liquid’s seal integrity. Core Advantages: Excellent low-temperature toughness, suitable for the entire cold chain logistics process, and expands the applicable temperature range of the infusion bag.

Applicable Scenario: Used for high-risk drug solutions such as liposomes, proteins, and peptides. These types of solutions have extremely high requirements for the chemical stability of packaging materials and must avoid degradation caused by the migration of packaging components.

Key Points of Toughening Formulation: Utilizes a three-layer co-extruded structure design, with SEBS-modified PP used only in the core layer (SEBS content within 12%). The inner and outer layers are made of high-purity medical-grade PP, forming a "barrier - support - barrier" protective structure. The core layer's modified PP provides toughness, while the high-purity PP in the inner and outer layers ensures safe contact with high-risk drug solutions, preventing SEBS and additives from directly contacting the solution.

Core Advantage: Precisely balances toughness and safety by isolating modified components through structural design, meeting the stringent packaging requirements of high-risk drug solutions.

4. Disposable γ-Ray Sterilized Infusion Bag

Applicable Scenario: Disposable infusion bags that need to undergo γ-ray sterilization. The γ-ray sterilization process may cause degradation of the PP substrate and reduce toughness, necessitating formulation optimization to enhance radiation resistance.

Key Points of Toughening Formulation: SEBS content is about 11%, and medical-grade radiation stabilizers (such as hindered phenol antioxidants) are added to the formulation to inhibit γ-ray damage to the PP molecular chains. The synergistic effect of SEBS and radiation stabilizers ensures the infusion bag's toughness and bending resistance, while maintaining stable performance after sterilization without aging or embrittlement.

Core Advantage: Excellent radiation resistance, with post-sterilization performance retention ≥90%, meeting the sterility requirements and reliability of disposable medical products.

The toughening solutions for four types of infusion bags use medical-grade SEBS, which must pass ISO 10993 biocompatibility certification and relevant medical packaging material standards. It features high purity, low impurity content, and stable performance. Compared with similar medical-grade modified materials, our medical-grade SEBS offers significant cost-performance advantages, helping companies control production costs while ensuring medication safety and product performance.