I. High resilience, wide weather resistance, transparent TPE application fields II. Substrate Selection and Process Key Points

This type of TPE is mainly used in scenarios with high requirements for transparency, rebound, low precipitation, and weather resistance, especially for thermoplastic processing and secondary overlamging.

1. Adult products field

The representative products are transparent/translucent bodies and accessories, their hardness range is Shao 00~30A, using low oil filling process, the oil filling amount is controlled at 30~60 parts, the core advantages are reflected in high transparency, high rebound performance, low permanent deformation rate and excellent weather resistance, and need to meet food-grade or medical-grade compliance standards when used.

2. Transparent elastic toys field

Covering elastic balls, suction cups, water filling toys, soft rubber accessories and other products, the hardness is set at Shao 20~50A, and it must strictly comply with EN 71-3, ASTM F963 toy safety standards to ensure that no substances precipitate and ensure the safety of use, especially for children.

3. Consumer electronics packaging and button field

Representative products include headphone stems, data cable connectors, transparent buttons, anti-slip rings, etc., the hardness is controlled at Shao 30~60A, with transparent/translucent texture, comfortable feel, excellent bending resistance and weather resistance, the key precautions are to achieve good adhesion with PP, PC, ABS and other substrates, and at the same time effectively prevent whitening during use, to ensure the appearance and structural stability of the product.

4. Sports and Leisure Equipment Field

Products mainly include handles, non-slip mats, resistance bands, and swimming goggle seals, with a hardness range of Shore 40~70A. The low oil-filled design provides core advantages such as high resilience, wear resistance, weather resistance, and transparency, suitable for outdoor and fitness scenarios. They need to have UV resistance and sweat resistance.

5. Medical and Food Contact (Non-Implantable) Field

Representative products include transparent seals, suction bulbs, catheter connectors, and nipples/teething rings, with a hardness range of Shore 30~60A. The low oil-filled process ensures high transparency and low migration characteristics, and they can withstand steam and standard sterilization procedures. Products must strictly comply with relevant standards such as FDA 21 CFR 177 and ISO 10993, while ensuring no odor, meeting the safety requirements of medical and food contact applications.

1. Substrate Selection

Prioritize high molecular weight SEEPS for high resilience; blend with medium molecular weight SEEPS to balance processability. For high transparency, prioritize low molecular weight SEEPS and blend with medium molecular weight SEEPS to improve strength.

2. Comparison with Other Substrates

Compared with TPU: SEPS-based TPE is softer and its rebound is closer to rubber, with better low-temperature toughness, but slightly inferior in oil resistance and abrasion resistance; suitable for transparent, high-rebound, and low-permanent-deformation applications.

Compared with SEBS-based TPE: SEPS has slightly better rebound and heat resistance, making it more suitable for high-rebound, low-oil-filled, weather-resistant transparent products.

Compared with PVC: Non-halogen, environmentally friendly, without plasticizer migration, better weather and aging resistance; suitable for high-end transparent, food, or medical applications.

3. Processing Technology

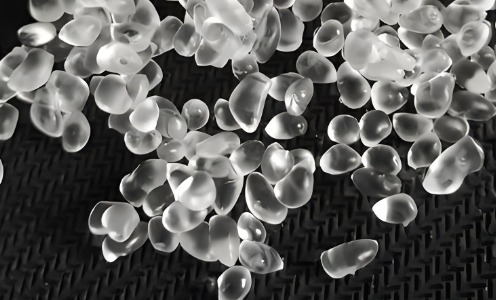

Oil Filling Control: Use low oil content (30–60 parts hydrogenated white oil) to avoid increased haze and oil separation; for high-transparency systems, avoid fillers/color masterbatch as much as possible and perform vacuum degassing.

Processing Temperature: Extrusion 190–210℃, injection molding 195–215℃; mold temperature 30–50℃, ensure adequate holding pressure to reduce shrinkage and weld lines.

Compliance Requirements: For toys, food, or medical products, conduct migration, heavy metal, and VOC testing; select compliant additives and white oil.