Although adhesive traditionally has created one of the biggest hurdles to effective recycling, recent innovations offer new opportunities.

Although adhesive traditionally has created one of the biggest hurdles to effective recycling, recent innovations offer new opportunities.

The search for stronger, more adaptable adhesives is ongoing. According to recent research, that search may come down to adding a dash of salt to two special polymer ingredients known as polyzwitterions, or PZIs. New research from a Florida A&M University-Florida State University (FAMU-FSU) College of Engineering team led by Hoyong Chung, an associate professor in the Department of Chemical and Biomedical Engineering, shows a new way to create adhesives by using the natural attraction between positively and negatively charged materials. The work was recently published in Journal of the American Chemical Society.

The entire life cycle of a product, or the system into which the product flows, should be considered to identify additional carbon reduction potential.

Packaging of adhesives and sealants can take many forms, and the best packaging for a product depends on a number of factors, such as dispending specifications, application environment, and cost.

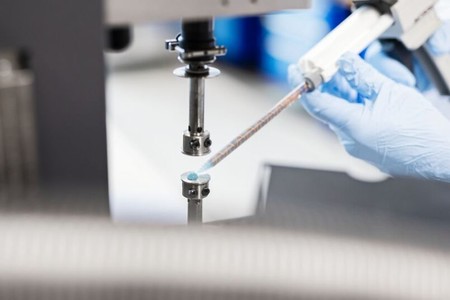

Many manufacturers of medical devices, point-of-care and near-patient testing products, and medical wearables are reassessing and upgrading their assembly fluid dispensing capabilities.

The Indian market for Styrene Copolymer experienced different trends in October 2024, influenced by demand-supply dynamics and global market developments. According to the studies by ChemAnalyst, Prices for Styrene Copolymer reduced by approximately 1.4% during the month, because of declined demand in downstream sectors like packaging and automobiles. This trend was more strengthened by a further drop in base material styrene prices in the month. However, a recovery in feedstock prices during the middle of the month provided some stability and limited the extent of the price decline for Styrene Copolymer.

Packsize®, a market leader in sustainable, right-sized, on-demand packaging, announced a new partnership with Henkel Adhesive Technologies to enhance the company’s sustainable product offerings, providing innovative solutions that help businesses reduce their environmental impact. This partnership exemplifies Packsize’s prioritization of strategic partnerships in its go-to-market strategy.

H.B. Fuller to showcase Swift®melt 1892 at Labelexpo India 2024. The event is to be held at INDIA EXPO CENTRE & MART, Greater Noida - Delhi NCR, Uttar Pradesh, India from Nov 14-17, 2024.

In October 2024, the U.S. Styrene market experienced ongoing price shifts due to diminished demand fluctuations in feedstock prices and a challenging economic scenario. Styrene prices showed significant reductions, mainly influenced by the volatility in the feedstock markets. Key feedstocks, such as ethylene and benzene, showed different trends, impacting the Styrene production landscape. Ethylene witnessed significant price declines in early October, due to a temporary oversupply following hurricane-induced supply chain delays. Benzene prices also saw substantial reduction in costs, reflecting subdued demand from the downstream sectors.

The adhesives and sealants market is critical to numerous industries, including construction, automotive, aerospace, packaging, and electronics. These products are essential for bonding, sealing, and protecting materials, which is crucial in product durability and performance. As industries evolve and technology advances, the adhesives and sealants market continues to grow, driven by increasing demand for high-performance materials and sustainable solutions. According to a report available from research firm Growth Market Reports, the global adhesives and sealants market size was $60.78 billion in 2022 and is likely to reach $94.27 billion by 2031, expanding at a compound annual growth rate (CAGR) of 5.1% during the forecast period of 2023 to 2031. The market growth is attributed to the rising demand for adhesives and sealants in various industries such as construction, automotive, furniture, and packaging.

Research and Markets (RM) anticipates that the global adhesives and sealants market size to reach US$ 99.5 Billion by 2032, exhibiting a growth rate (CAGR) of 4.6% during 2023-2032. The market is experiencing steady growth driven by the increasing demand for adhesives and sealants across various industries, growing environmental awareness, surging demand for eco-friendly formulations, ongoing research and development (R&D) activities, and evolving consumer preferences for convenience and aesthetics.

At 2024 Battery Show North America, Henkel showcased material solutions that enable its OEM and battery manufacturer customers to reduce impact across all emissions categories, while improving battery performance, safety, cost and process efficiency. Battery debonding technology is critical to enable end-of-line repair and disassembly of batteries at end of life.