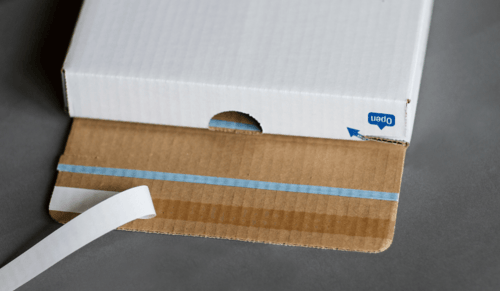

The COVID-19 pandemic fundamentally reshaped the way the world operates, and one of the most significant shifts was the exponential growth of the global e-commerce market. As physical stores shut their doors during lockdowns, online shopping surged to unprecedented heights, and this trend shows no signs of slowing down. By 2025, the global e-commerce market is projected to reach a staggering $4.32 trillion USD in revenue, and by 2029, that number will rise to $5.89 trillion USD, with 3.6 billion users expected worldwide.