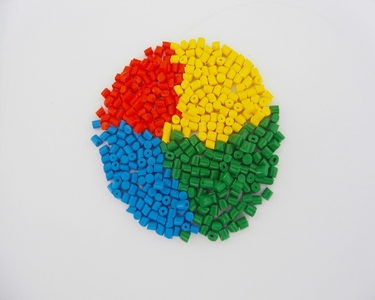

HEXPOL TPE knows it could always be easier being green which is why it has added new compounds to its Dryflex Green family of biobased TPEs. Dryflex Green is a family of thermoplastic elastomer compounds based on raw materials from renewable resources such as plant and vegetable crops.