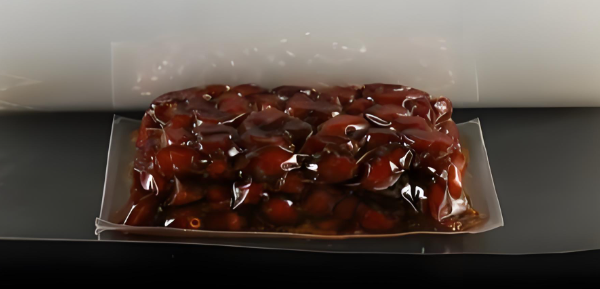

Keywords: PA/PP co-extruded film; toughening; high temperature resistance; polar compatibility; delamination PA/PP co-extruded films are widely used in high-temperature sterilization packaging, vacuum packaging, and room-temperature fresh-keeping packaging for foods such as meat, cooked food, and condiments. This is attributed to the PA layer’s excellent barrier properties against oxygen, moisture, and odors, as well as the PP layer’s superior heat-sealability and cost-effectiveness. The film structure consists of PA layer → adhesive layer (PP-based) → PP layer; the toughness of this three-layer structure directly determines the film’s puncture resistance, tear resistance, and processability. Therefore, the toughening system must be selected based on specific application scenarios. Detailed solutions are as follows: I. Core Toughening Principles Toughening of PA/PP co-extruded films requires balancing interlayer compatibility and service condition resistance: The toughening agent must be compatible with the substrate of the corresponding layer (PA or PP). It must match the film’s temperature resistance and aging resistance requirements. Avoid migration of the toughening agent, which may cause interlayer adhesion or performance degradation. II. Scenario-Specific Toughening Solutions 1. Scenarios Requiring High Temperature Resistance and Aging Resistance (e.g., 121℃ high-temperature sterilization, outdoor light-proof packaging) Toughening System: High-flow SEBS + Maleic Anhydride-grafted SEBS (SEBS-g-MAH) Mechanism: High-flow SEBS exhibits good compatibility with both PA and PP, improving the film’s puncture resistance (by 20%~30%) and low-temperature toughness (no brittleness at -20℃). The anhydride groups of SEBS-g-MAH react with the terminal amino groups of PA and polar sites of PP, enhancing both interlayer adhesion and substrate toughness to prevent delamination after high-temperature sterilization. The hydrogenated structure of SEBS endows the film with excellent thermo-oxidative aging resistance, maintaining stable toughness for over 6 months in outdoor use. Suitable Layers: Universal for PA layer, adhesive layer, and PP layer Recommended Ratio (based on the mass of the corresponding layer’s substrate): SEBS 3%~5% + SEBS-g-MAH 2%~3% Select high-flow SEBS grades with ethylene content ≥50% to avoid reduced heat-seal strength due to excessive addition. 2. Scenarios Without High Temperature/Aging Resistance Requirements (e.g., room-temperature vacuum packaging, short-term fresh-keeping packaging) Toughening System: POE + Maleic Anhydride-grafted PP (PP-g-MAH) Mechanism: POE (Polyolefin Elastomer) has excellent compatibility with PP, significantly improving the PP layer’s tear resistance at a cost only 50%~60% of that of SEBS systems. As a compatibilizer, PP-g-MAH enhances the interfacial bonding between POE and PP, while strengthening the interlayer adhesion between the adhesive layer and PA/PP layers to prevent delamination. Suitable Layers: Mainly for PP layer and adhesive layer; PA layer requires matching with a small amount of PA compatibilizer (e.g., EAA) Recommended Ratio: POE 5%~8% + PP-g-MAH 3%~4% When adding to the PA layer, compound with 5%~8% EAA to avoid reduced toughness caused by poor compatibility between POE and PA. 3. Scenarios Balancing High/Low Temperature Resistance, Aging Resistance, and Cost Control (e.g., cold chain packaging, room-temperature long-shelf-life food packaging) Toughening System: POE + SEBS + PP-g-MAH Mechanism: POE reduces the overall cost of the toughening system through its cost advantage, while SEBS’s hydrogenated structure ensures the film’s high-temperature resistance (100℃) and aging resistance. PP-g-MAH acts as a universal compatibilizer, coordinating the compatibility of POE, SEBS with PA and PP, and balancing interlayer adhesion and overall toughness. Performance: The film can withstand -30℃ low-temperature transportation and 90℃ short-term sterilization, with puncture resistance improved by 25%~35% and cost reduced by 30%~40% compared to pure SEBS systems. Suitable Layers: Universal for PA layer, adhesive layer, and PP layer Recommended Ratio (based on the mass of the corresponding layer’s substrate): POE 3%~4% + SEBS 2%~3% + PP-g-MAH 2%~3% III. Key Supporting Process Optimization Points Co-extrusion Temperature: PA layer: 240~260℃ Adhesive layer: 220~240℃ PP layer: 200~220℃ Ensure full melting and dispersion of the toughening agent. Substrate Selection: PA layer: Prefer PA6 (viscosity 2.7~3.0) PP layer: Select homopolymer PP (melt flow rate 2~5g/10min) Improve compatibility with toughening agents. Additive Matching: Add 0.1%~0.3% antioxidant (1010+168) to prevent degradation of the toughening agent during high-temperature processing.