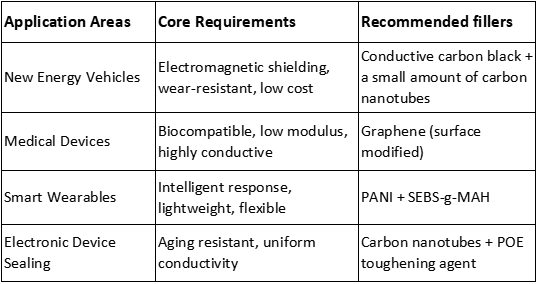

TPE conductive modification imparts materials with conductivity, electromagnetic shielding, and intelligent response characteristics by adding functional conductive fillers to the formulation. The finished products can be processed into forms such as cushioning pads, patches, films, and sealing strips, making them widely applicable in high-end fields such as new energy vehicles, medical devices, and smart wearables. They also combine physical protection with temperature/pressure sensitivity, electromagnetic protection, and electrical signal transmission functions. Filler selection needs to carefully balance conductivity, mechanical properties, processability, and application requirements. I. Characteristics of Mainstream Conductive Fillers and Selection Logic 1. Carbon Black (Traditional Classic Type) II. Filler Adaptation Solutions for Different Scenarios III. Processing Technology and Common Problem Solutions

Core Advantages: Strong conductive stability, bulk resistivity can be as low as 10²~10⁴ Ω·cm, low cost, suitable for large-scale production;

Key Selection Points: Preferably use small particle size (20~50nm), high-structure conductive carbon blacks (e.g., acetylene black, Ketjenblack), which have large specific surface area and easily form conductive networks, reducing the required filler amount (recommended loading 15%~30%);

Precautions: High filler loading can reduce TPE tensile strength by 20%~40% and increase hardness, requiring 5%~10% toughening agents (e.g., POE) to improve toughness, suitable for scenarios with moderate mechanical performance requirements (e.g., sealing strips for new energy vehicle battery packs).

2. Graphene / Carbon Nanotubes (High-Performance Type)

Core Advantages: Excellent conductivity and mechanical reinforcement, requiring only 0.5%~5% addition to achieve 10³~10⁵ Ω·cm, while improving TPE tensile strength by 15%~25% and tear resistance by 30%;

Key Selection Points: Graphene should be few-layer with 1~5nm thickness; for carbon nanotubes, single-wall or double-wall types are preferred (diameter 5~10nm). Both should be surface-modified with silane coupling agents (e.g., KH550, KH560) to reduce agglomeration and enhance compatibility with the TPE matrix;

Applicable Scenarios: Conductive patches for high-end smart wearables, electromagnetic shielding films for medical devices, especially suitable for products requiring lightweight, thin materials and high mechanical performance.

3. Polar Functional Materials (Intelligent Responsive Type)

Core Advantages: Polar materials like PEO (polyethylene oxide) and PANI (polyaniline) can impart temperature-sensitive and pressure-sensitive properties to TPE. For example, PEO-based conductive TPE shows significantly increased conductivity with rising temperature, while PANI-based materials can modulate electrical signals with pressure changes;

Key Selection Points: PEO should have a molecular weight of 10⁴~10⁶ and be blended with TPE at 5%~15%; PANI tends to agglomerate and requires SEBS-g-MAH (maleic anhydride grafted SEBS) as a compatibilizer (3%~8%) to solve dispersion issues;

Applicable Scenarios: Pressure-sensitive sensors for smart wearables, temperature-monitoring patches for medical devices, suitable for functional scenarios requiring dynamic response.

1. Processing Technology Optimization

Mixing: Use the "dry mix first, then batch mix" process. Pre-mix the conductive filler with the TPE matrix in a high-speed mixer for 5–8 minutes, then mix in a 160–180°C batch mixer for 10–15 minutes to ensure uniform filler dispersion;

Molding: Control injection molding temperature at 170–190°C and extrusion temperature at 165–185°C to avoid filler oxidation or decomposition due to high temperatures.

2. Common Problem Solutions

Uneven conductivity: Reduce the amount of filler added at one time, add in batches, and use 0.5%–1% dispersant (e.g., calcium stearate);

Reduced mechanical properties: For carbon black systems, add 5%–10% elastomer toughening agent; for graphene/carbon nanotube systems, keep filler content ≤5%;

Insufficient sensitivity in smart response: Adjust the PEO/PANI ratio, increase the amount of SEBS-g-MAH compatibilizer, and improve dispersion uniformity.