There was a time long past when the only rubber we had was natural rubber latex, polyisoprene. Straight out of the tree, natural rubber latex isn't good enough. It gets runny and sticky when it gets warm, and it gets hard and brittle when it's cold. Tires made out of it wouldn't be much good unless one lived in some happy land where the temperature was seventy degrees year round.

In 1839, the time was before there were any cars to need tires, but the idea of a useable rubber was still attractive. One person trying to make rubber more useful was named Charles Goodyear, a tinkerer and inventor, and by no means a successful one at this point. While goofing around in his kitchen with a piece of fabric coated with a mixture of rubber latex, sulfur and a little white lead, he accidentally laid it on a hot stove top. It began sizzling like a mass of really smelly bacon or (strangely enough) burning rubber. When he took a look at this mass of rubber, he found it wouldn't melt and get sticky when it was heated, nor would it get brittle when he left it outside overnight in the cold Massachusetts winter. He called his new rubber vulcanized rubber.

Here the sulfur formed bridges. It tied all the polymer chains in the rubber together. These are called crosslinks as in the picture below. Bridges made by short chains of sulfur atoms tie one chain of polyisoprene to another, until all the chains are joined into one giant supermolecule.

Yes, an object made of a crosslinked rubber is in fact one single molecule. A molecule big enough to pick up in your hand.

These crosslinks tie all the polymer molecules together. Thus, when the rubber gets hot, they can't flow past each other, nor around each other. This is why it doesn't melt. Also, they aren't easily broken apart from each other.

Other kinds of rubber, which chemists call elastomers that can be crosslinked include polybutadiene, polyisobutylene, and polychloroprene.

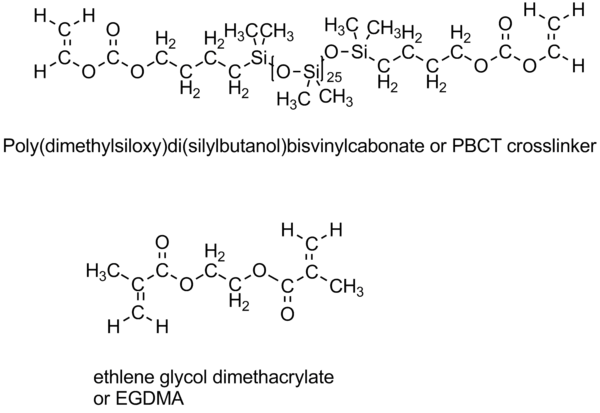

But rubber isn't the only thing that can be crosslinked. Plastics are also made stronger by crosslinking. Formica is a crosslinked material, and the material used in many plastic "glass" for screen doors (for example) or in bathtubs surrounds are crosslinked acrylates and methacrylates. One common crosslinker is EGDMA (shown below). Even contact lenses are crosslinked using special and expensive difunctional monomers like the one shown below as well.

Crosslinked polymers are usually molded and shaped before they are crosslinked. Once crosslinking has taken place, usually at high temperature, the object can no longer be shaped. Because heat usually causes the crosslinking that makes the shape permanent, these materials are called thermosets. This name distinguishes them from thermoplastics, which aren't crosslinked and can be reshaped once molded. Interestingly, the first thermoset was again polyisoprene. The more sulfur crosslinks put into the polyisoprene, the stiffer it gets. Lightly crosslinked, it's a flexible rubber. Heavily crosslinked, it's a hard thermoset.

Crosslinked polymers can also be coatings, adhesives, and electronic parts. Crosslinked materials can't dissolve in solvents, because all the polymer chains are covalently tied together. But they can absorb solvents. A piece of a crosslinked material that has absorbed a lot of solvent is called a gel.

Crosslinking makes both elastomers and plastics stronger, but there is a problem. Because crosslinked materials don't melt, it is very hard to recycle them. One answer to this problem is to create crosslinks that can be reversed or undone. One family of materials using reversible crosslinks are thermoplastic elastomers.