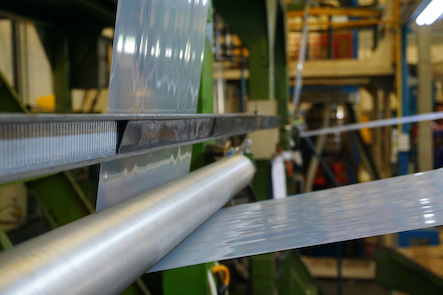

Huntsman: New TPU grade with improved properties for fire hoses and textiles Huntsman has developed a new thermoplastic polyurethane (TPU) grade for technical extrusion parts and blown film applications that is said to offer significant improvements over previous generation technologies when it comes to durability, production efficiency and reducing manufacturing waste. According to the company, Irogran A 85 P 4394 HR TPU is the latest addition to a well-established family of elastomer products from Huntsman, which are renowned for their performance in a diverse range of industrial and consumer applications. Developed in close partnership with Huntsman’s customers, Irogran A 85 P 4394 HR TPU has greater tensile strength than the standard Irogran A 85 P 4394 elastomer grade originally developed in 2004. The new grade also offers improved film extrusion quality and high melt strength, which makes it ideal for blown film applications. Delivering better resistance to force in its melted state, which makes it less likely that an extruded film will break during production, Irogran A 85 P 4394 HR TPU can help to lower scrap rates, improve manufacturing throughput and cut waste in blown film processing. Irogran A 85 P 4394 HR TPU offers improved film extrusion quality and high melt strength, which makes it ideal for blown film applications. (Source: Huntsman) The new grade was developed to solve the problems of customers in diverse markets including: · TPU lay flat hoses used in high pressure industrial and municipal applications e.g., firefighting · Textile lamination – as a breathable, waterproof layer for rugged performance apparel. In the manufacture of TPU lay flat hoses, Irogran A 85 P 4394 HR TPU is applied via the “extrusion through-the-weave” process. In this application, the product’s greater tensile strength is highly advantageous – helping the resulting hoses cycle between periods of being tightly coiled and then extended and put under high water pressure levels. In the case of fire hoses, this pressure can typically be in the region of 8 bar and 20 bar (800 kPa and 2,000 kPa; 116 psi and 290 psi). When it comes to textile lamination, Irogran A 85 P 4394 HR TPU is a good material for creating a waterproof, breathable film in rugged performance apparel (including gloves and footwear). Blown to create an extremely thin layer, which is then added to fabrics, the TPU provides the protective properties needed to create high performance outdoor garments. Adhering well to different kinds of fabrics, the TPU can aid the stretch and recovery of the materials it is used on. The nature of the grade also means the resulting films can be engineered to have different surface finishes, including gloss, smooth and matte effects. Trent Shidaker, Global Marketing Director, Elastomers at Huntsman, said: “Irogran A 85 P 4394 HR TPU is a highly versatile and durable elastomer. Soft to the touch, it’s ideal for apparel applications that need to stay in contact with the wearer for hours at a time; but it’s also strong enough to be used in municipal and industrial hoses that have to perform under the toughest conditions. Applying its development expertise, our elastomers team has enhanced the processing properties of Irogran A 85 P 4394 HR TPU, without compromising the key performance attributes expected of products in this range – namely excellent hydrolytic resistance; fantastic wear performance; and microbial resistance. The result is an elastomer that can enable manufacturers to work more efficiently, cut waste and create longer-lasting products; a compelling proposition for the markets we serve.” The basis of the chemistry of the new TPU goes back to 2004 when the flagship product was first developed. Later variations of the product were developed to create the family of elastomer products from Huntsman that customers have learned to know and love. The new TPU’s greater tensile strength helps lay flat hoses cycle between periods of being tightly coiled and then extended and put under high water pressure levels. (Source: Huntsman) Other Irogran A 85 P 4394 TPU products available from Huntsman include: · Irogran A 85 P 4394 – a legacy product, launched in 2004, that was first introduced for thin wall technical parts, thin wall extrusion profiles, spiral hoses, cable jacketing and film and sheet. · Irogran A 85 P 4394 FCM – launched in 2015, this grade has a similar base chemistry to the standard version of Irogran A 85 P 4394 but is formulated with raw materials that are compliant with FDA regulations for food processing belts and has an NSF 61 rating (approved for potable water applications). · Irogran A 85 P 4394 UV – also launched in 2015, this product is fortified with proprietary additives that enable it to withstand UV exposure while maintaining excellent physical properties and appearance. This product is used for pneumatic tubing for airlines and industrial equipment and fracking hoses. Irogran A 85 P 4394 HR TPU is made at the Huntsman Polyurethanes manufacturing facility in Ringwood, IL, USA. https://www.gupta-verlag.com/news/technology/25328/huntsman-new-tpu-grade-with-improved-properties-for-fire-hoses-and-textiles