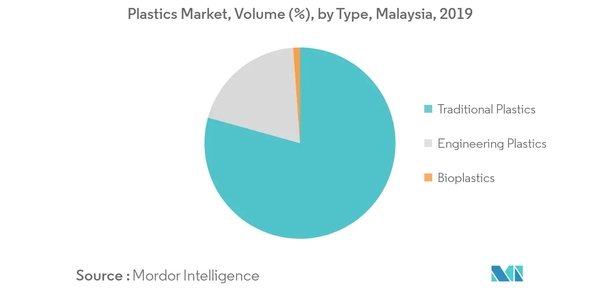

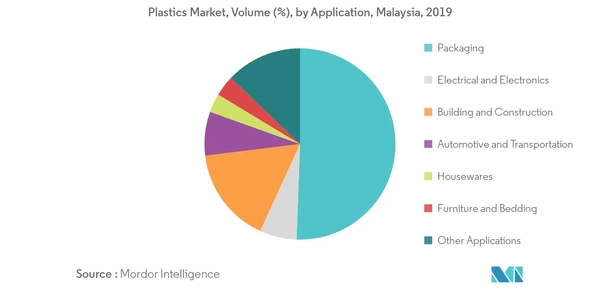

Market Overview The market for Malaysia plastics is expected to grow at a CAGR of around 4% globally during the forecast period. The major factor driving the growth of the market studied is the rising demand from the food & beverage packaging. Key Market Trends In Traditional Plastics, Polyethylene to Dominate the Market ●Presently, polyethylene has become one of the key products used in our daily life. It is primarily used in the packaging sector, which comprises of containers and bottles, plastic bags, plastic films, as well as geomembranes. It has various types, including HDPE and LDPE. ●The packaging industry has been experiencing drastic growth over the past few years. The increased demand for packaged goods has accelerated the demand for high-density polyethylene (HDPE). ●Owing to the increased disposable income and rising consumption of products, including packaged foods, personal care products, pharmaceuticals, etc., the HDPE market is growing drastically. ●The use of HDPE for plastic pipes in buildings is leading to the growth in the product’s market, owing to the rapid increase in Malaysia’s infrastructure sector. ●Malaysia’s construction industry is expected to grow over the forecast period, due to the newly established Pakatan Harapan Coalition, which continues to reduce government debt and expenditure by initiating large-scale infrastructure projects across the country. ●Following this coalition, the government has initiated the construction of two oil and gas pipeline projects in the country, worth USD 970 million each. Increasing Demand from Packaging Industry ●Packaging accounts for the largest application segment in the Malaysian plastics market. The prime reasons for the growing application of plastics in the packaging segment include better wear and chemical resistance, ease of molding, recyclability, puncture resistance, and high mechanical strength. ●Most commonly used plastics in the packaging industry include: ○High-Density Polyethylene (HDPE): It is the most common type of plastic used in the manufacturing of bottles and containers. HDPE provides excellent chemical resistance, thus also used for packaging of many household and industrial chemicals, including detergents and bleach. ○Low-Density Polyethylene (LDPE): It is used for packaging applications due to its toughness, flexibility, and relative transparency, etc. Its applications include flexible lids, bottles, and other wire and cable applications. ○Polyethylene Terephthalate (PET): It is clear and tough and possesses good gas and moisture barrier properties. It is most commonly used in beverage bottles and other injection molded consumer product containers. ○Polypropylene (PP): It has characteristics, such as excellent chemical resistance and a high melting point, making it a reliable choice for hot-fill liquids. It is used for flexible and rigid packaging applications and other large molded parts required for automotive and consumer products. ○Polystyrene (PS): It is a versatile plastic that can be both rigid as well as foamed. Its typical application includes protective packaging, foodservice packaging, bottles, and food containers. ●According to The Malaysian Reserve (local information provider owned by TMR Media Sdn Bhd) ○Malaysia’s annual per capita plastic packaging consumption is high among all the South-east Asian countries at 16.78 kg/person. The total household plastic packaging consumption in the country is estimated to reach 523,000 metric ton by the end of 2020. ○This consumption is mainly driven by private households, small businesses, and other end users, such as schools, hospitals, and government buildings. ●In 2019, despite the US-China trade tensions, robust demand from the country’s local plastic packaging manufacturers propelled its strongest gains. ●Also, the packaging industry has gained momentum after the COVID-19 outbreak with the government advising the people in the country to take all the necessary hygiene protection. Moreover, e-commerce has also augmented the demand for plastic packaging in the country due to the COVID-19 outbreak, as online delivery is rapidly rising with people avoiding public gatherings. Source:https://www.mordorintelligence.com/industry-reports/malaysia-plastics-mar