Adhesives can help make an electric vehicle lightweight. Electric vehicle adhesives are ideal replacements for mechanical fasteners in electric vehicle batteries. Electric vehicle adhesives offer several benefits such as even distribution of stress and load across bonded joints; improvement of strength; and efficient and flexible part design. Adhesives reduce or sometimes replace heavy mechanical fasteners in electric vehicle battery design. This enables to improve the efficiency of electric vehicles. Key Growth Drivers of Electric Vehicle Adhesives Market Electric vehicle adhesives make vehicles lighter, quieter, and safer compared to mechanical fastening methods such as welding, bolting, and soldering. Structural adhesives are known to distribute load evenly across a surface, resulting in better efficiency compared to mechanical fastening, which generates local stress in parts joined. Currently, around 15 kg of adhesives are used in a car on an average. This amount is likely to increase in the next few years. Electric vehicle adhesives are also employed in interiors, exteriors, and engine compartments of aircraft, due to their advantages over other types of adhesives. These adhesives carry higher weight loads and improve uniform distribution of the stress and strain across the joints. Electric vehicle adhesives also maintain integrity and strength of materials, as there is no hole, rivet, or fastening element to weaken the structure. These factors are anticipated to boost the demand for electric vehicle adhesives across the globe during the forecast period. Adhesives and sealants also play a significant role in body construction, paint, and vehicle assembly of hybrid and battery electric vehicles. Decreasing the weight of electric vehicles helps extend their range. Therefore, OEMs put significant effort into lowering the weight of components of the body, interior, and powertrain. Major Challenges for Electric Vehicle Adhesives Market Lucrative Opportunities for Electric Vehicle Adhesives Market Adhesives and sealants play a vital role in the advancement of vehicle electrification technology. They are estimated to remain at the forefront of the development of hybrid (HEV) and battery electric (BEV) vehicle battery cells, modules, packs, and motors. Source:https://www.transparencymarketresearch.com/electric-vehicle-adhesives-market.html

The automotive industry is continually working toward designing lightweight and fuel-efficient vehicles, which can reduce CO2 emissions significantly. Stringent regulations regarding CO2 emissions are being implemented across the globe. Electric vehicle adhesives play an important role in reducing CO2 emissions. These adhesives provide vehicles with structural strength. They possess the ability to bond various surfaces together.

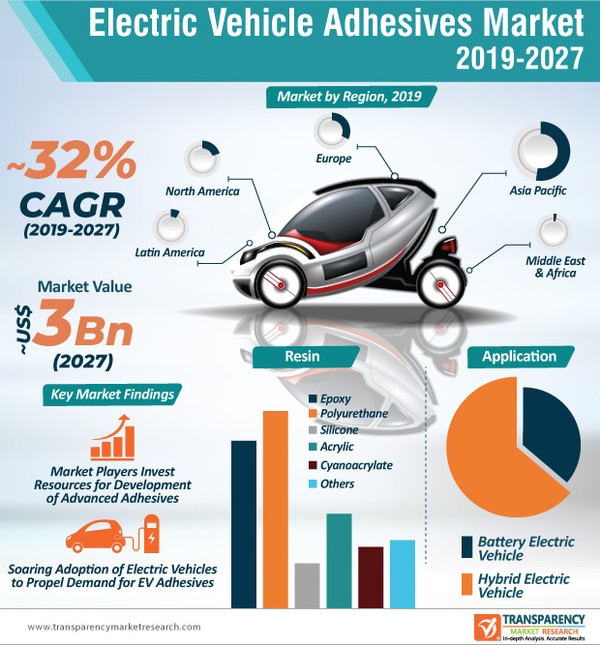

According to the Open Charge Map, a global public registry of electric vehicle charging location, about 150,000 charging stations are present across 75,000 locations around the world. Furthermore, more than 1 million electric cars were sold in 2017, according to the IEA Global Electric Vehicle (EV) Outlook 2018; China accounting for more than 50% of global sales. Thus, the ratio of on-road electric vehicles to that of charging stations is low. The number of charging stations installed in developing regions such as Latin America and Middle East & Africa is less compared to that in developed regions. This is expected to hamper the sale of electric vehicles, thereby adversely affecting the demand for electric vehicle adhesives.

The automotive industry is a key end user of electric vehicle adhesives. Demand for electric vehicle adhesives has been increasing due to the rise in requirements by automakers. For instance, these adhesives are employed in bonding similar and dissimilar materials; and substitution of traditional substrate materials by synthetic substrates. Increase in focus on environmental concerns is also boosting the demand for electric vehicle adhesives. Electric vehicle adhesives also address issues regarding engineering and design, as they are valued for their ability to resist vibration. They are also lightweight and help distribute stress over a wide area.

Leading Players Actively Engage in Joint Ventures and R&D Activities

Key players operating in the global electric vehicle adhesives market include

3M

Henkel AG & Company

KGaA

H.B. Fuller

DuPont de Nemours, Inc.

Arkema S.A.

Permabond LLC

Ashland Inc.

LORD Corporation

PPG Industries, Inc.

Avery Dennison Corporation

Evonik Industries AG

Illinois Tool Works Inc.

Dymax Corporation

Wacker Chemie AG

Sika AG.