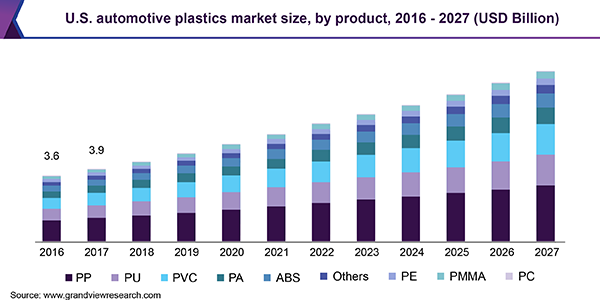

The global automotive plastics market size was valued at USD 35.7 billion in 2019 and is anticipated to progress at a CAGR of 11.1% from 2020 to 2027. Global recovery in the automotive sector, improved vehicle design capabilities, and increasing focus on vehicle weight reduction and emission control are the key factors boosting the growth of the market for automotive plastics. Plastics are widely used in automotive components and parts owing to easy manufacturing, possible sourcing from renewable raw materials, and improved designs. Polypropylene (PP), polyvinyl chloride (PVC), acrylonitrile butadiene styrene (ABS), and polyurethane (PU) are the most common materials used for vehicle part and component applications. Plastics undergo five different stages while recycling including sorting, washing, shredding, identification and classification, and extruding into final component or product. Improvements in recycling processes have forced manufacturers to use high-performance automotive plastics. Usually, an average car consists of 5.8 to 10% of plastics, depending on fuel-efficiency standards and performance requirements, with consumption in vehicular equipment accounting for over 105 kg in an average car. This percentage is expected to increase owing to growing demand from consumers for high-performance, lightweight, and fuel-efficient vehicles, thereby augmenting demand for automotive plastics over the years to come. Weight reduction also offers a cost-effective way to reduce greenhouse gas (GHG) emissions and fuel consumption, conserving non-renewable crude oil reserves. For example, for every 10% weight reduction in a vehicle would improve fuel economy by 5 to 7%. However, 1 kg weight decrease can reduce 20 kg of carbon emission. Plastic monomers are polymerized using chemical reactions and catalysts to form polymers and co-polymers and are turned into polycarbonate (PC), polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), polystyrene (PS), and other such polymerized materials. These materials possess far better properties than their respective monomers and are extremely stable for use in molding and fabrication. Designing a vehicle is a critical factor as it is subjected to various external forces and the possibilities of high impacts. Thus, to preserve the structural integrity of a vehicle, the materials used in its production become important factors for safety and stability. Although they are relatively cheaper than metals, their design parameters and manufacturing equipment are highly expensive, which is expected to pose a challenge to industry participants. Source:https://www.grandviewresearch.com/industry-analysis/automotive-plastics-market