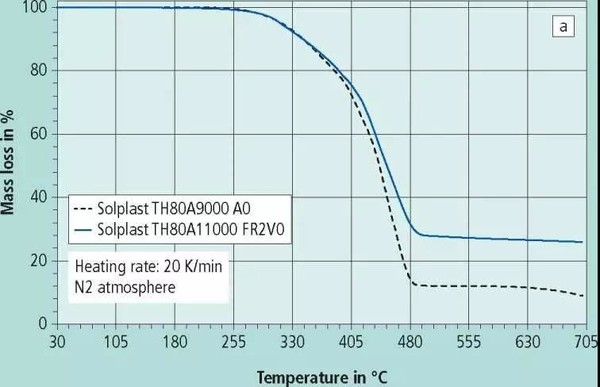

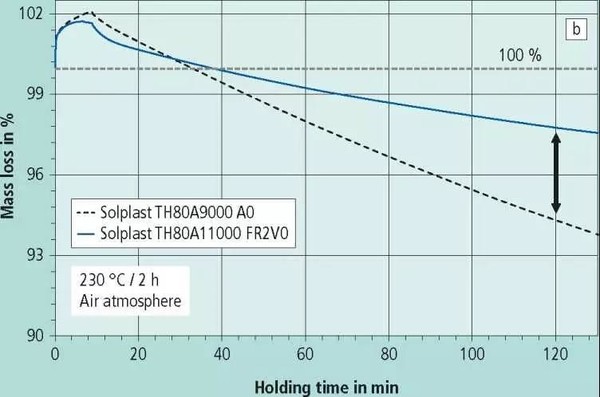

Flame retardant (FR) compounds are widely used today in multiple technical applications such as electronic devices, e-mobility or in building and construction. Many of these applications like cable connectors, battery charging systems or casings for electronic devices, contain flame retardant cables, sealing, grommets, gaskets or soft-touch elements. As a consequence flame retardant thermoplastic elastomers (TPE) are gaining more and more attention in scientific work and R+D as well as in industries and markets. Nevertheless, TPS compounds typically contain rather high amounts of mineral oil as plasticizer and processing aid. The mineral oil acts usually as an intrinsic fire accelerator. This makes it challenging to obtain a high FR performance without losing the specific TPS properties such as high elongation and ductility. In the past halogenated FR additives or high amounts of mineral FR additives have been. Thermal stability is the ability of a material to maintain its properties at a given temperature. On the other hand, thermal degradation means the deterioration of those properties. Therefore, thermal and thermo oxidative stability are important characteristics to define the usability and thermo-plastic processability of these new TPS HFFR compounds. Figure 1 compares the thermal degradation behavior of a standard TPS compound (80 Shore A) with the new TPS HFFR compound (80 Shore A). The thermal degradation was measured by means of thermogravimetric analysis (TGA) in nitrogen atmosphere and in air. Fig. 1: (a) Thermal degradation of Solplast TH80A9000 A0 and Solplast TH80A11000 FR2V0. (b) Thermal stability of Solplast TH80A9000 A0 and Solplast TH80A11000 FR2V0 in air at 230 °C for 2 h (Source: Albis) The thermal degradation behavior of the new TPS HFFR compounds in nitrogen atmosphere is comparable to standard TPS compounds. However it can also be seen that the residual mass at 700 °C is significantly higher for the TPS HFFR compounds indicating stronger char formation. Furthermore, it reveals obviously better thermal stability in air for the new TPS HFFR compounds than for the standard non-flame retardant TPS compound. The measurement of OIT (Oxidative Induction Time) by DSC at different temperatures confirms the higher thermo-oxidative stability of the new TPS HFFR compounds. The higher thermo-oxidative stability is found especially at temperatures higher than 190 °C. The measurements above show that the new TPS HFFR compounds provide similar thermal stability and even better resistance to thermo oxidative degradation than conventional non-flame retardant TPS compounds and can therefore widely be used for typical melt processing technologies such as extrusion and injection molding. Source:TPE Magazine