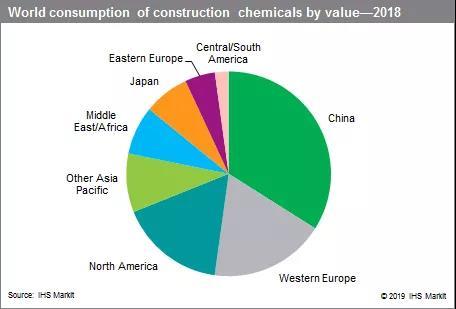

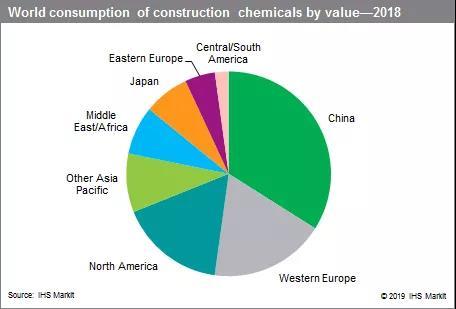

Worldwide, the construction industry contributes about 13% to the global GDP, and is one of the most important elements of every economy. The industry consumes a great deal of chemicals and polymers, which are used to enable or ease manufacturing or improve the performance of existing construction materials. China alone accounted for about 35% of the total value of specialty construction chemicals, followed by Western Europe and North America. In China, the consumption of specialty chemicals dropped from 2012 to 2018 on a volume basis, but consumption on a value basis increased. The increase was attributed primarily to a replacement of first- and second-generation concrete water-reducing agents with higher-priced third-generation superplasticizers, which are required for the construction of higher-quality structures.China by far consumes the most concrete admixtures of any region, and will continue to do so, as almost half of all planned global high-rise buildings are scheduled to be built in China through 2025. These tall buildings are almost always made of concrete.The following pie chart shows world consumption of construction chemicals on a value basis:There is no generally accepted definition of construction chemicals. The list can be quite extensive. The construction chemicals market includes materials such as concrete admixtures; asphalt emulsions; adhesives and sealants; roof, floor, and waterproofing coatings; and spray insulation foams. These specialty chemical products are covered in depth in this report. The remaining construction chemicals market includes products like bituminous membranes for waterproofing, grouts, mortars, cement additives, expanded polystyrene insulation boards, and many other products that are more commodity-like.The overall global construction market is forecast by IHS Global Insight to grow at an average annual rate of about 3.4% from 2018 to 2023. Growth prospects are good, but at lower levels than in recent years. Construction spending in China grew at a real rate of about 11% annually during 2006–16, but has slowed in recent years. Chinese construction spending is forecast to grow at a 4–5% compounded annual rate between 2018 and 2023, with growth led by the nonresidential segment. The residential sector is expected to slow as a result of overbuilding in 2010–16.The construction industry is quite diverse with many users. There are numerous suppliers of construction chemicals, including many small and midsized companies that operate on a regional basis. There are a limited number of multinational producers, including BASF, Sika, MAPEI, Grace Construction Products (GCP), and others. These companies focus on the production of concrete admixtures, asphalt emulsions, adhesives and sealants, specialty coatings, and spray insulation foams, as well as other products.Some of the chemicals used by the construction industry have been growing rapidly in recent years, even in the mature developed areas like North America, Western Europe, and Japan, including the following:· Concrete admixtures, increasingly used for producing superstrong concrete needed to build taller buildings that have relatively large open areas on lower floors to maximize rental fees. Demand for admixtures and cement additives has been increasing, particularly as a result of the increased performance requirements placed on concrete and mortar, especially in urban areas and for infrastructure construction.· Polymeric modifiers in asphalt, which improve wear resistance, reduce noise, increase skid resistance, prevent softening at low temperatures, and increase longevity with reduced maintenance costs.· Insulation and sealants applied on-site, which can function as air/water barriers in walls or on roofs. Use is growing as builders and architects work to reduce building energy consumption to meet revised building codes and green building guidelines.· Sealants, use of which has been growing as builders and home owners want to increase the overall durability and energy efficiency of structures.· Roof coatings, used to extend the lives of existing roofs to reduce “tear downs” or to provide solar reflectance (“cool roofs”), serving to keep buildings cooler in hotter climates to reduce air conditioning costs.In 2012, the US EPA implemented new and stricter requirements for homes to be awarded the Energy Star label. The EPA states that homes certified under the new requirements are at least 15% more efficient than those built to the 2009 International Energy Conservation Code. The EPA also notes that the total number of certified homes is now greater than 1.4 million. Energy Star has helped Americans reduce utility bills by $23 billion, which has saved 210 million metric tons of greenhouse gas emissions.