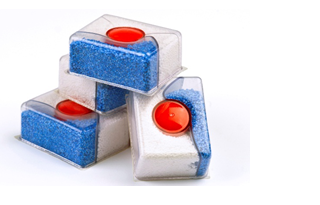

Plastics today have to meet more specific requirements than ever – with significant consequences for production: To make plastics products extra-elastic, robust or air-impermeable, the raw materials employed have to have highly specialized properties. Many of these raw materials are difficult to process and production processes are often very complex. At Booth B1-1221 in Hall B1 at Fakuma 2017 in Friedrichshafen , Kuraray, a globally leading specialty chemicals manufacturer, is presenting new Septon Bio as well as Hybrar, Eval EVOH, Genestar PA9T and Mowiflex: Plastics that have application-oriented properties while also permitting efficient processing. Plastics have a multitude of functions: They enhance the impact-absorbing effect of floorcoverings, protect foods in packages from contamination and loss of aroma, or ensure the long-term durability of composite materials. However, many of these plastics call for special processing and are poorly compatible with widely-used production methods such as injection molding. Specialty chemicals producer Kuraray has therefore developed application-oriented plastics solutions – for ease of processing and efficient handling in production. Kuraray is presenting its broad plastics product portfolio at the 25th staging of the Fakuma trade show, the international flagship show for plastics processing,, in Friedrichshafen. At Booth B1-1221 in Hall B1, the polymer specialist will be reporting on: · bio-based thermoplastic elastomer Septon Bio · Hybrar, the thermoplastic elastomer with outstanding vibration-damping properties · Eval EVOH adding high barrier properties to complex coinjected shapes · heat, water and chemical resistant Genestar PA9T · Mowiflex, a water-soluble polymer that lends itself well to processing by injection molding. Broad Portfolio of Plastics for Everything from Automotive to Packaging The hydrogenated styrene farnesene block copolymer (HSFC) Septon Bio is the new and bio-based TPE raw material from Kuraray. Thanks to its high flow ability and outstanding adhesion, it is extra-easy to process, does without plasticizers and, in addition, has a broader damping range than conventional hydrogenated styrene block copolymers (HSBC). Septon Bio is the outcome of collaboration with Amyris, which derives the basic material B-farnesene from sugarcane. Septon Bio is put to use in many different applications such as adhesives, sealants, compounds and coatings, and is used for polymer modification. The highly elastic styrene block copolymer Hybrar absorbs shocks and vibrations – even without integrated plasticizer. Available in hydrogenated and non-hydrogenated grades, it features good moldability and robustness. This makes Hybrar suitable for sports equipment, automotive and acoustic components, and floorcoverings. The EVOH copolymer Eval is used as a barrier resin in co-extrusion and co-injection processes. Employed in extremely thin layers just a few millimeters thick in food and medicine packages, it provides a functional barrier versus oxygen and thus extends product quality and shelf life. In addition, it allows plastic automotive fuel systems to comply with strict fuel vapour emission standards. At Fakuma, Kuraray will explain how Eval as a highly effective barrier can be used in complex co-injected structures – to make barrier applications previously not possible with coextrusion processing. [Image 1] Extremely thin and aroma-secure: The copolymer Eval EVOH from Kuraray protects foods against oxygen in packages with barrier layers just a few micrometers thick. The polyamide engineering plastic Genestar is a PA9T and has outstanding properties such as low water absorption and high heat and chemical resistance. Genestar can be precision-processed by extrusion and injection molding and is particularly suited to applications in electronic and automotive components. [Image 2] Heat- and chemical-resistant: Exhibited by Kuraray at Fakuma 2017, Genestar PA9T is a highly robust engineering plastic that is ideal for processing by extrusion and injection molding. The polyvinyl-alcohol-based polymer Mowiflex is water-soluble and at the same time highly suitable for thermoplastic processes such as injection molding. Its low shrinkage means shorter process times and lower material usage. Mowiflex is ideal for water-soluble packages for agrochemicals, for automatic dishwasher tablets and as a support material in 3D printing. [Image 3] Customized and water-soluble: The polymer Mowiflex from Kuraray can be injection-molded for the production of water-soluble packages in different shapes for automatic dishwasher tablets.